Car seat sensors must be foolproof

As a very important part of automobile safety system, seat belt is closely related to seat occupancy sensor.When a passenger seat on, the sensor will be activated and connect to ECU,if the seat belt is not locked, the alarm from car speaker will remind the passenger to fasten the safe belt .FSRTEK has all kinds of seat sensors available in various shapes and sizes for customer to choose.At the same time, FSRTEK has rich experience in project development,able to design and customize the seat sensor for the specified seat.

FSRTEK design and production of seat sensors fully consider the requirements of the vehicle in different environments, all the sensor need to pass strict test before put into production,the tests include the high and low temperature test, trigger force test, product life test, voltage resistance test, waterproof test and a series of safety tests, to ensure the stability of the product performance.A qualified car seat sensor must be foolproof!

Seat sensor has more and more application now!

Now the seat sensor are not only used in the car seat belt alarm system, it can also be used in restaurants, library seat occupy statistics system, hospital patients in the bed or not identification system.

Seat Sensors Details

|

F-1543(200*165mm) |

F-1595 (110.22*117mm) |

F-1491(83.77*177mm) |

F-1425 (196.2*131.6mm) |

F-1676 (278.4*234.94mm) |

F-1358(122.55*108.16mm) |

|---|---|---|---|---|---|

|

F-1354(168.56*155.15mm) |

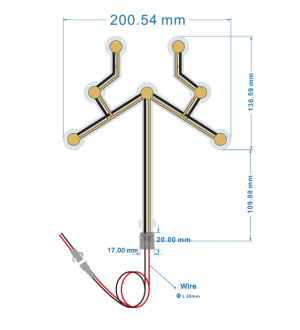

F-1631(200.54*136.59mm) |

F-1521(272.5*24mm) |

F-1685(250*48mm) |

F-1629(300*213.79mm) |

F-1365 (300*150mm) |

|

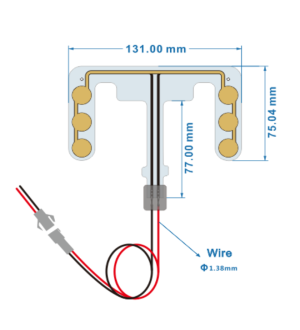

F-1536 (131*75.04mm) |

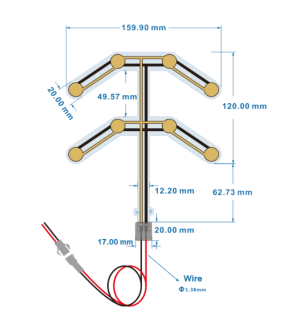

F-1421(159.9*120mm) | ||||

|

More seat sensor standard products see PDF : |

| System diagram | Product Structure |

|---|

| Optional Connector | |||||

|---|---|---|---|---|---|

| BS01 | BS02 | BS03 | BS04 | BS05 | BS06 |

| Size | Customized | Working temperature | -30~80℃ |

| Single sensor point trigger force | 150g~180g | Insulation impedance | 20MΩ |

| Seat trigger force | 30~ ∞ kg | Static resistance | 10MΩ |

| Working voltage | <50V DC | Closed resistance | 0-150Ω |

| Working current | <100mA | Work life | 1 million times |

| Response time | <5 ms |

| 1. Select sensors that fit the shape and size of the seat.Please note that the contact point of the sensor cannot be placed in the seat groove(See chart 1), otherwise the sensitivity and performance will be affected. |

Chart 1

Chart 2

| 2. Select the sensor suitable for the seat size, too big sensor cannot be installed, too small sensor will have a blind area. |

| 3. The thickness and hardness of the sponge above the sensor have a great influence on the sensitivity of the sensor(See Chart 2).The best thickness of sponge is suitable for 2-3cm. The sponge should be medium hardness.The hardness of the surface under the sensor also has a great influence on the sensitivity of the sensor.The best trigger force and sensitivity can be achieved by adjusting the thickness and hardness of the sponge. |

Projects Using Seat Sensors

Custom Your Own MEMBRANE FORCE SENSORS!

We accept orders for custom seat sensors. If you need to customize production of seat sensors according to your needs, please let us know the information as below:

working size and shape

Tell us your demand size and shape of seat sensor, we can quickly complete the Preliminary confirmation.

lead length

Since seat sensor‘lead have no standard for length and materials , you need to provide the lead specifications in your mind.

connector type

We have six standard connector type for you to choose from.

trigger weight

The sensing area,force measure range,thickness and force repeatable of products you need.

Application

Tell us your application, our engineers can confirm your choice will be the best one, and give more suggestions to meet your budget.

FSRTEK 8 dimensional custom system

TO SPEAK WITH OUR PRE-SALE ENGINEER

If you have any application requirements, please contact our engineers and we will provide you with the most suitable solution .